Things to consider when designing a label. What you can and cannot write.

Once you have sorted out the packaging for that exclusive skin care range, you need to consider what to do about displaying the information on the product.

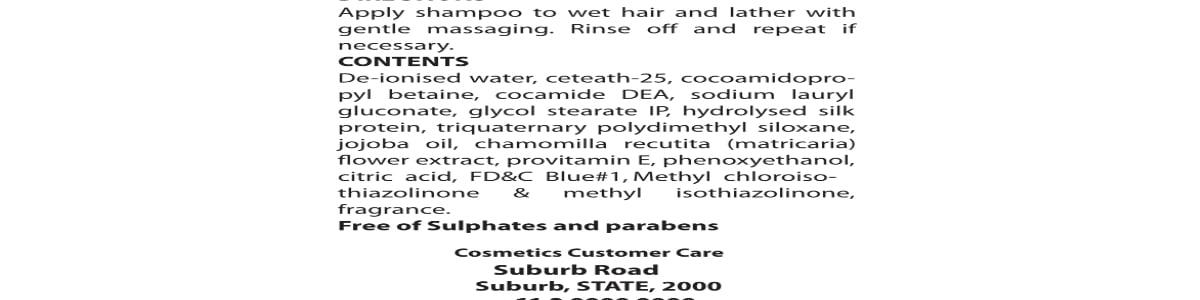

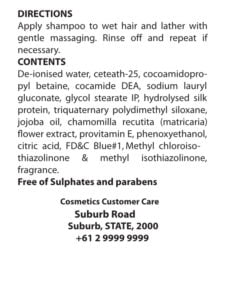

Here is a mock example of a label.

Firstly there are 2 considerations

- Should the packaging be printed on? Or

- Should the packaging have a label applied?

Both of these have their advantages and disadvantages.

Printing directly onto the packaging (screen printing)

The advantage of printing directly onto the packaging is that:

- It is considered permanent and in most cases cannot be affected by the material inside,

- It looks smooth on the packaging with no edge ridges of a label

- The print can be very striking and clear and even raised (3-D effect)

- It is the best method to use on tubes

- Once the machine is set up and aligned, runs are much quicker than when having to apply labels.

The constraints are that

- You are often forced to print a significant minimum quantity, most times in the thousands ; it is deemed very cost ineffective to have short runs

- You are left with printed packaging which may take a considerable time to use up and take up a considerable space to store

- If you make a mistake on the print then it is permanent and only removed by discarding the whole packaging

- In the process of starting up the print run, there can be quite a few items of the packaging that will not print well. These items cannot be used as they will look wrong. This happens when there is the need to align the different print runs for the different colours. This affects you most if you are supplying the packaging and you have a definite number you need (an example is if you supply 1,000 bottles you may only get 950 back).

Printing on labels

The advantage of printing on labels which can be affixed to the packaging is

- Regardless of how many labels you print ranging from 100 to 10,000, the storage of the rolls or sheets take much less space than storing printed packaging

- If there are any errors in the label, the discard process is much less costly as it is just a case of throwing away the labels

- If the labels are applied to the wrong product the situation can be simply rectified by removing the label unless the label is paper which unfortunately can leave glue or material behind.

- There are many more ways to print on labels as opposed to straight on the packaging. Gold or silver foil stamping look very impressive on vinyl type labels

- It is possible to have a booklet type label where more information can be displayed or where several languages need to be included other than English (especially useful for the European Union requirements)

- You need to only label the number of products you wish to fill and not significantly more

- There is no packaging wastage necessary.

The disadvantages are

- The cost to apply the labels needs to be considered when evaluating feasibility of using labels.

- It can take longer to apply the label than to have the packaging printed

- In most cases the packaging can definitely show where the label is, due to the edge surrounds of the label

- Labels on tubes can develop creases when the tube is squeezed to expel the product

- Economically it becomes non feasible for large runs such as 10,000 units or more.

Creating the information to be displayed

Once a decision has been made on which way the information will be presented then it is necessary to develop a unique logo and a name for the brand and the product inside.

Your skincare manufacturer and formulator should provide you with an ingredients list in descending order of concentration which is mandatory to be printed on the label. In order to cover all markets in the world it would be safest to give both the common name (which is most necessary in the US market) as well as the International Nomenclature of Cosmetic Ingredients (INCI) name (most necessary in the EU market).

Some examples

- Cocos nucifera (coconut) oil.

- In the case of herbal extracts the common and Latin names as well as where it is extracted from eg. Chamomila matricaria (chamomile) flower extract

Next you need to use your creative skills to make a little story about the product and how to use it. For example “tea tree originated in Aboriginal times. Wounded natives found that bathing in the pools of water which tea tree grew in, aided the wounds to heal much quicker rather than just leaving the wounds untreated. Tea tree is called as such because tea was hard to come by in the early colonial days so settlers improvised by boiling the leaves of the tea tree fronds.”

Next write a short description for application and use of the product. For example “place a small amount on affected areas and spread on the skin followed by gentle tapping into the skin for maximum absorption”.

It is best to try to associate this product with other products you may have in your range. For example “After cleansing your face with “my brand” face cleanser you should use this “my brand” toner followed by “my brand” moisturiser.”

A contact address and/or a website must be included along with the name of your business. Writing Post Office Boxes as the contact is very unethical and can lead to difficulties with the authorities especially when the public wish to make inquiries or complaints.

The front of the label should clearly show “my brand”, what it is (eg. Super Hydrating Face Moisturiser) and the volume or weight. It is best to write this as several options as all products have not the same properties. For example use a weight such 50 g/ml, or 4.5 fl oz (when distributing to the American market).

Next is what you can “claim” your product does. Be careful not to make therapeutic claims such as healing, antiseptic, scar removing, disinfectant, etc as this may incur the wrath of authorities such as the Therapeutic Goods Administration (TGA) or the Federal Drugs Administration (FDA). They may either force you to withdraw the product or prove the product was made in a proper authorised facility. They may even force you to have double blind tests to prove the validity of your claims. This can be extremely costly. Your contract manufacturer can usually help you to word your descriptions so that you will not cross that fine line into the therapeutic world.

Finally you are advised to find a good, knowledgeable graphic designer to prepare your artwork so it looks professional. Unfortunately MS Word and MS Publisher documents are not used by industry and whilst they are acceptable to convey an idea, they are programs capable of converting into a printers graphics file except at a great added cost.